We use cookies to enable the proper functioning of our website, personalize content and advertisements, provide social media features, and analyze traffic. We also share information about your use of our website with our social media, advertising, and analytics partners.

Thermoplastic Carbon

Leading the Global Thermoplastic Revolution

Thermoplastic technology is an advanced manufacturing process that involves heating thermoplastic material to a pliable state, forming it under high pressure, and then cooling it to set the shape. This method offers high production efficiency, supports diverse market demands, and reduces manufacturing costs. Additionally, the material is recyclable, aligning with global environmental sustainability goals.

Designed for Sustainability

Tougher & Better Impact Resistant

Comfortable & Stable Ride

Consisted Quality

Rapid Production

15 Min Per Frame

Lightweight

Each thermoplastic bicycle frame is carefully designed to reduce weight while enhancing stiffness, ensuring superior performance and agility on both urban streets and rugged trails.

Automated Production

Our highly automated production process ensures fast and efficient manufacturing, with production cycles as short as 15 minutes per unit. Helps reduce labor costs, shorter lead time and increase overall efficiency.

Impact Resistance

Sustainable and Eco-Friendly

We are committed to sustainability by using recyclable thermoplastic materials. Our goal is to reduce the carbon footprint during production and support green cycling initiatives.

6 Stages of Thermoplastic Carbon Fiber Reinforced Polymer

-

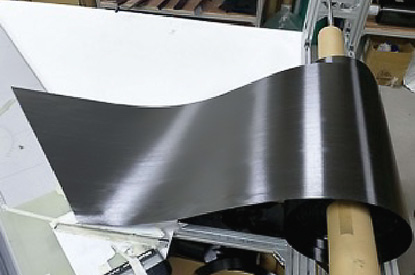

Step 1. Prepreg

Carbon fibers are impregnated with a thermoplastic resin to create a prepreg sheet.

-

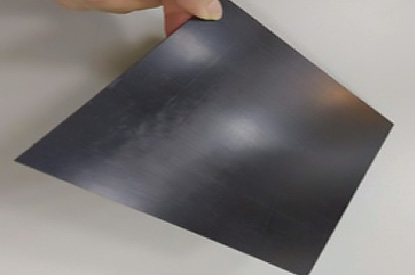

Step 2. Blank

Cut and layered into specific shapes and orientations

-

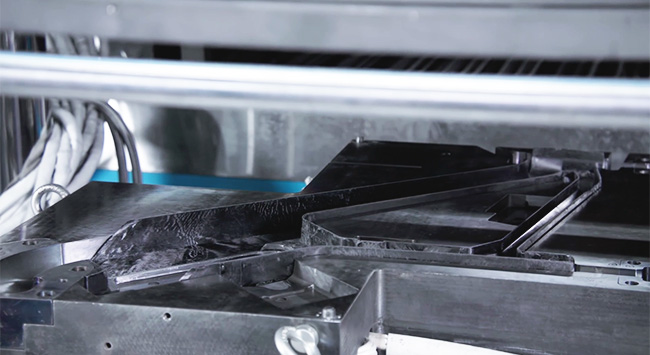

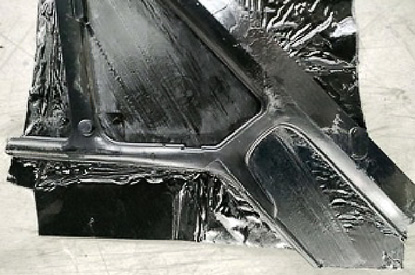

Step 3. Monocoque

Single-piece (monocoque) structure using high temperature and high pressure

-

Step 4. Joining

Using advanced welding specific to thermoplastic materials

-

Step 5. Crushed Scrap

Excess material from the molding stages is collected, crushed, and reused

-

Step 6. Plastic Pellet for Injection

Further processed into plastic pellets are used to create new components

For more information, please contact us to explore future cycling solutions together!